COMPANY PROFILE

Dongguan Hepburn Steel Co., Ltd. was established in 2011, with a warehouse area of more than 10000m² and steel inventory of more than 2000tons. After more than 10 years of development, it has become one of the best quality tool steel suppliers in Dongguan. As a agent of large Chinese steel mills such as Baowu(formerly Bao Steel), Shao Steel, An Steel, Xiang Steel, Dalian Steel, Zhongye Steel, Tiangong, Daye Special Steel, Great-wall Steel. We specialize in distributing tool steel and die steel to more than 20 countries in Europe, America, Asia and Africa. We have all kinds of processing equipments, such as 15 sets of horizontal sawing machines, 2 sets of high-precision circular sawing machines, 3 sets of vertical sawing machines, 3 sets of gantry milling machines, 3 sets of gantry grinding machines , etc. We are able to provide services such as cutting, milling, grinding, heat treatment, metal parts machining and precision CNC machining. Hepburn always aims at product quality and customer benefit. With professional inspection equipment such as ultrasonic flaw detection, metallographic structure analysis, tensile testing, hardness testing and so on. We strictly follow the international standards of inspection to ensure that we provide every customer with high quality products. We have a professional foreign trade sales team with 13 years of export experience. Efficient and hassle-free One-stop service can be provided, including raw material procurement, customized processing, heat treatment processing, etc. Everything to make your business more convenient!

Metal Machining

Metal machining is the mechanical processing of metal elements that focuses on removing the extent of the material. Part produced in the said process is usually much lighter than the block of beginning material and has a desired shape and is made according to the requirements of the customer.

Precision plastic parts processing injection mold manufacturers mobile power shell plastic molding mold ABS white$400.00-1,000.00 / metric tonSHOP NOW

Precision plastic parts processing injection mold manufacturers mobile power shell plastic molding mold ABS white$400.00-1,000.00 / metric tonSHOP NOW High precision injection molding manufacturers plastic mold injection molding open grinding plastic mold injection molding$400.00-1,000.00 / metric tonSHOP NOW

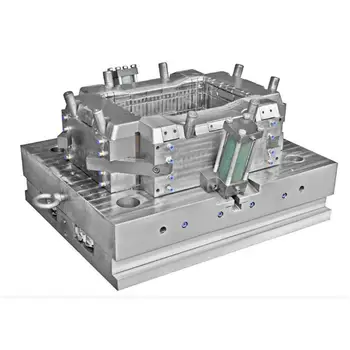

High precision injection molding manufacturers plastic mold injection molding open grinding plastic mold injection molding$400.00-1,000.00 / metric tonSHOP NOW Plastic mold injection manufacturers quickly high precision manufacturing abrasive injection molding household appliances shell$400.00-1,000.00 / metric tonSHOP NOW

Plastic mold injection manufacturers quickly high precision manufacturing abrasive injection molding household appliances shell$400.00-1,000.00 / metric tonSHOP NOW Customized mold making for auto parts medical parts mould manufacturer making plastic toilet seat cover parts injection mold$400.00-1,000.00 / metric tonSHOP NOW

Customized mold making for auto parts medical parts mould manufacturer making plastic toilet seat cover parts injection mold$400.00-1,000.00 / metric tonSHOP NOW Expert Custom Alloy Mold Manufacturing Durable Reliable and Affordable$400.00-1,000.00 / metric tonSHOP NOW

Expert Custom Alloy Mold Manufacturing Durable Reliable and Affordable$400.00-1,000.00 / metric tonSHOP NOW Custom Alloy Molds Precision Engineering for Your Unique Manufacturing Needs$400.00-1,000.00 / metric tonSHOP NOW

Custom Alloy Molds Precision Engineering for Your Unique Manufacturing Needs$400.00-1,000.00 / metric tonSHOP NOW Enhance Product Quality with Expertise Innovative Mold Solutions Custom Designs Fast Turnaround Precision Mold for Every Project$400.00-1,000.00 / metric tonSHOP NOW

Enhance Product Quality with Expertise Innovative Mold Solutions Custom Designs Fast Turnaround Precision Mold for Every Project$400.00-1,000.00 / metric tonSHOP NOW Expert Mold Makers Tailored Designs for Every Industry Application High-Quality Molds Made to Order Boost Production Efficiency$400.00-1,000.00 / metric tonSHOP NOW

Expert Mold Makers Tailored Designs for Every Industry Application High-Quality Molds Made to Order Boost Production Efficiency$400.00-1,000.00 / metric tonSHOP NOW